Asset Protection in Extreme Environments

What needs to be considered in the selection of a concrete protection system for Extreme Environments?

Background – What is extreme?

Concrete, carbon steel, even stainless steel, can deteriorate rapidly in many hostile industrial environments. The CAT (corrosive, abrasion and thermally hot) environment in cement plants, steel plants, mineral processing, refineries, smelters, power generation plants, glass plants, waste incinerators and the refractory industry can be very demanding. For example, the flue gases found in these environments contain SO3, SO2, HCl, CO2, NOx and particulate matter. They are extremely corrosive and abrasive. And they are hot. Structures such as baghouses, stacks, fans, ducts, rotary kilns and their foundations require extreme protection. “Hot corrosion” is a general term for “high-temperature corrosion”; it includes high-temperature oxidation, sulphidation and carbonization. New ceramic-based alloys are available for these demanding applications.

Design life – Budget compliance

The first important question to ask when selecting a new protection system is – What is the required design life – 2, 5, 10 or 20 years? And, is frequent or regular maintenance feasible? The CAT environment requires careful consideration. If nothing is done, corrosion will cost in terms of maintenance, downtime, and efficiency. If the wrong solution is chosen, it will again cost in maintenance, downtime, and efficiency. The specification must meet the agreed design life and the intended maintenance-free period.

Management of surface preparation during application

This is the basic foundation of any protection system. The preparation process must be effective and consistent. Inadequate surface preparation is a leading cause of premature failure.

Inherent chemical resistance requirement

The particular chemical environment needs to be identified and understood. Steel and concrete are widely used engineering materials. However whilst strong in certain mechanical aspects, unprotected, they are extremely susceptible to a wide variety of chemical attacks. The specification for any protection system must address the specific chemical resistance requirements. EpiMax offers a range of protection systems engineered for specific project requirements.

Abrasion resistance

The specification for any protection system must address the abrasion performance requirements including impact and abrasion resistance. Any protection system applied must exhibit excellent adhesion and have a bond strength that is maintained over the life of the system.

Thermal resistance

The specification for any protection system must address the thermal performance requirements including impact and abrasion resistance. Any protection system applied must exhibit excellent adhesion and have a bond strength that is maintained over the life of the system.

Practical application characteristics

The particular needs of the structure including the practical aspects of access and application are important considerations in any project. EpiMax supplies protection systems that can be applied by spray or roller in thicknesses of 150 – 3000 microns per pass. Trowel applied systems can achieve 75 mm thickness.

Concrete Protection Systems

Concrete is an excellent engineering material. It has been used to build all types of structures for many centuries. It has proven to be extremely versatile and exhibits good strength in compression. However unprotected concrete has very limited chemical and abrasion resistance. Concrete structures in the resources and heavy industry sector are subjected to some of the harshest environments known. Many structures in these industries must resist a powerful combination of forces including those of chemical, abrasive impact and thermal action.

Processing chemicals can easily penetrate porous, unprotected concrete surfaces. Corrosive chemicals not only penetrate but quickly attack concrete, but if they leak, splash, or spill onto floors, drains, bunds, walls or other concrete infrastructure, premature failure will occur. In addition, chemicals can pass through the concrete slab into the soil below, eventually reaching groundwater under the facility. The abrasive impact can rapidly damage concrete. Wear on concrete floors, due to lift truck activity, skidding, scraping and sliding is abrasive. It causes a breakdown of the concrete leading to the formation of further abrasive particles which accelerate the damage. High temperatures accelerate the chemical deterioration of concrete. Chemical activity is temperature-dependent. In hotter environments, concrete needs even more protection.

EpiMax is your source for the latest proven developments in performance protection systems. This is all we do. Our systems build on breakthrough technologies (extreme chemically resistant third-generation epoxy novolac chemistry, high-performance water-based chemistry, new polyaspartic chemistry).

At EpiMax we pride ourselves in the chemical technology of the systems we offer, the knowledge value involved in their use and our overall responsiveness. EpiMax has built its reputation on a construction engineering foundation. Our experience has been forged on an impressive variety of civil, environmental, industrial, mining, defence and general services construction.

This success has been proven through partnerships with forward-thinking architects, consultants, engineers, application contractors, project managers and materials testing agencies. We believe in teamwork, respect and integrity.

Our primary focus is:

- Floor Protection Systems

- Industrial Concrete Protection Systems

- Green Star Protection Systems

- Water and Wastewater Processing Protection Systems

- Foundation Protection Systems

- Extreme CAT (Corrosion, Abrasion and Thermal) Protection System

EpiMax: Expertise Applied, Answers Delivered

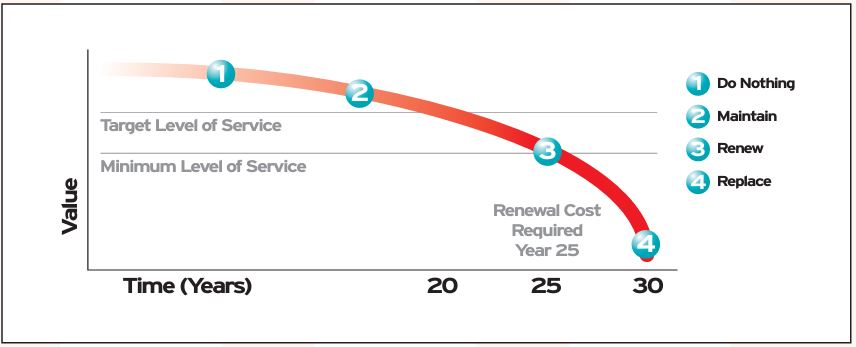

Typical Asset Depreciation

Our Product Range Includes

Concrete Resurfacing

- EpiMax 222

- EpiMax 222AR

- EpiMax 465

Concrete Coating

Foundation Protection

Applications – Typical industries include:

- Chemical containment

- Mine maintenance facilities

- Waste processing facilities

- Chemical plants

- Power generation

- Steel plants

- Cement plants

- Smelting operations

- Battery recycling

- Oil and gas industry

- Automotive industry

- Foundries

- Metal refineries

- Wastewater treatment facilities

- Glass factories

For more information on any of our products please contact us today.

CATEGORIES

Knowledge value at your fingertips

SIGNUP NOW

Signup to the Knowledge Centre.