Ensuring long term structural integrity.

What needs to be considered for products used in Precision Grouting and Concrete Repair?

Practical Application Characteristics

The particular needs of the project including the practical aspects of access and application are important considerations.

EpiMax supplies systems that have been developed and proven over decades in very demanding applications. A key component of our R&D process is ensuring that we build error-tolerant systems which offer straightforward and repeatable field applications.

We are also well equipped to develop innovative technology for new and challenging applications.

Reliable Adhesion Capability

One of the critical factors governing the achievement of any effective concrete repair is good adhesion at the repair interface of the repair material and the concrete substrate. Concrete is a fundamental building block in the developed world.

However, new concrete simply does not bond well to old concrete. Adhesion is also critical in precision grouting applications where loads need to be distributed throughout the foundation.

Specify systems that are self-priming.

Non-Shrink Curing

The dimensional stability of any structural material refers to its potential to change shape or volume.

If a repair mortar or a structural grout shrinks during the curing process, it cannot claim to be dimensionally stable. Shrinkage will at best, initiate mechanical stresses within the structure, and at worst, cause delamination or mechanical breakdown.

Specify systems that offer non-shrink curing.

Adequate and Controlled Flow

The ease with which a precision grouting system enters small cavities and travels under large structures is critical. A repair system also needs to make intimate contact with the micro-pores in the prepared concrete surface. Any tendency to separate during mixing or handing will cause problems.

Well-engineered grouting systems operate as Newtonian liquids and have a linear relationship between shear rate and shear stress.

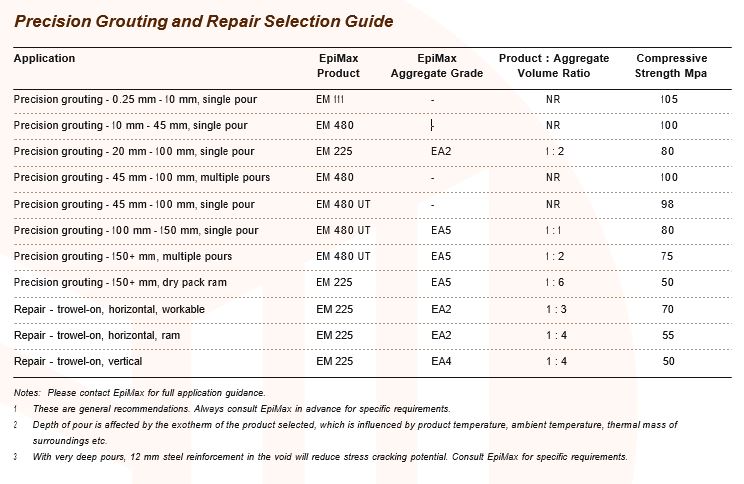

Mechanical Performance

The mechanical properties of any precision grouting system or concrete repair system can be very important. These performance characteristics include compressive strength, tensile bond strength, shear strength as well impact resistance. Not only must the system meet the requirements for the project, but it must also meet them reliably in the field application.

High-performance applications also demand creep resistance and, sometimes, higher temperature ranges.

Inherent Chemical Resistance

Concrete is a widely used engineering material. However whilst strong in certain mechanical aspects, unprotected concrete is extremely susceptible to a wide variety of chemical attacks. The specification for the repair system must address the chemical resistance requirements. Chemical resistance is also critical for machinery and foundation grouting applications.

Sustainability – Whole of life

Sustainability is related to the quality of life in a community – whether the economic, social and environmental systems that make up the community are providing a healthy, productive, meaningful life for all community residents, present and future.

With regard to protection systems, sustainability should consider the “whole product life cycle”. This includes production, application, service life and disposal. Volatile Organic Content (VOC) is an important measure of a protection system’s

environmental impact. Our products meet or exceed the requirements of IEQ.13.1, Green Star Office Interiors, and Indoor Environment Quality. EpiMax is a member of the Green Building Council of Australia.

Design Life – Budget Compliance

The first important question to ask when selecting a new system is – What is the required design life– 2, 5, 10 or 20 years? And, is frequent or regular maintenance feasible? It is virtually impossible to keep any concrete structure from cracking. Without proper protection, these cracks become the routes through which moisture, salt, acid rain and other chemicals can begin the degradation process on concrete remarkably quickly. The specification must meet the agreed design life and the intended maintenance-free period.

EpiMax is your source for the latest proven developments in precision grouting and repair systems. Our systems build on breakthrough technologies polymer technologies as well as adding proven science in aggregate grading and selection.

All too often, the correct choice and selection of aggregates is overlooked. Aggregates can simply be thought of as inert filler that is included simply for reasons of economy. However, closer examination reveals the complex roles and influences that the correct choice of aggregate plays in the properties of both freshly mixed and cured grouts and repair systems. Changes in composition, gradation and size will all alter the character and engineering performance of the mix.

In summary, aggregate science involves balancing the selection of, and the proportions between, coarse and fine high strength aggregates to match project placement methods, desired finish, cured performance and economy.

EpiMax offers a proven range of blended aggregates that are:

- Inherently high strength

- Silt and debris free

- Graded for particular applications

- Kiln-dried

- Packaged in sealed plastic containers ideal for site storage

Our Product Range Includes

Our Product Range Includes

- EpiMax 111

- EpiMax 225

- EpiMax 480/480UT

- EpiMax 480 Express

- EpiMax 480 HTG

- Max 480 UW

- EpiMax 575

Applications – Industrial and Mining Equipment

- Presses and stamping machines

- Compressors and turbomachinery

- Process storage tanks

- Wind turbine foundations

- Precision grouting of mining equipment

- Weighbridge grouting

- Slew bearing grouting

- Test equipment grouting

- Structural anchoring

Applications – Transportation Grouting

- Train and crane grouting

- Road bridge grouting

- Tunnel construction

- Light rail anchoring

Applications – Structural Injection Grouting

- Drying shrinkage

- Thermal contraction or expansion

- Settlement

- Lack of appropriate control joints

- Overload conditions/ restraint of movement

Applications – Structural Concrete Repair

- Spalled concrete repair

- Mechanical repairs

- Chemical protection

- Carbon fibre strengthening

Case Study – Certified Flow, Certified Strength

Fiberglass Reinforced Plastic (FRP) has been used to build corrosion resistant mineral processing storage tanks for more than 40 years. The operating conditions associated with mineral processing often require materials of construction that can withstand processing acids and acid chlorides at temperatures up to 90°C.

However these tanks must be grouted securely to the concrete foundation, otherwise, they can crack and leak during service.

EpiMax 480 UT Precision Extreme Life Epoxy Grout was selected for a critical project in New Caledonia where exceptional flow, (up to 14 m) through varying gaps

(< 1mm to 25 mm), and strict mechanical performance was required before third party certification was achieved.

EpiMax supplied more than 50,000 litres of performance grout over a 4-week time frame for this very demanding project.

CATEGORIES

Knowledge value at your fingertips

SIGNUP NOW

Signup to the Knowledge Centre.